Protective Door Industries

15700 Lathrop Ave.

Harvey, IL 60426-5118 USA

Overview

Blast / Pressure / Missile / Bullet / Tornado Resistant Products

Protective Door Industries’ (PDI’s) blast or pressure resistant doors, windows and hatches assure blast protection and dependable service under critical conditions whether accidental or malicious for interior or exterior environments including:

Slide title

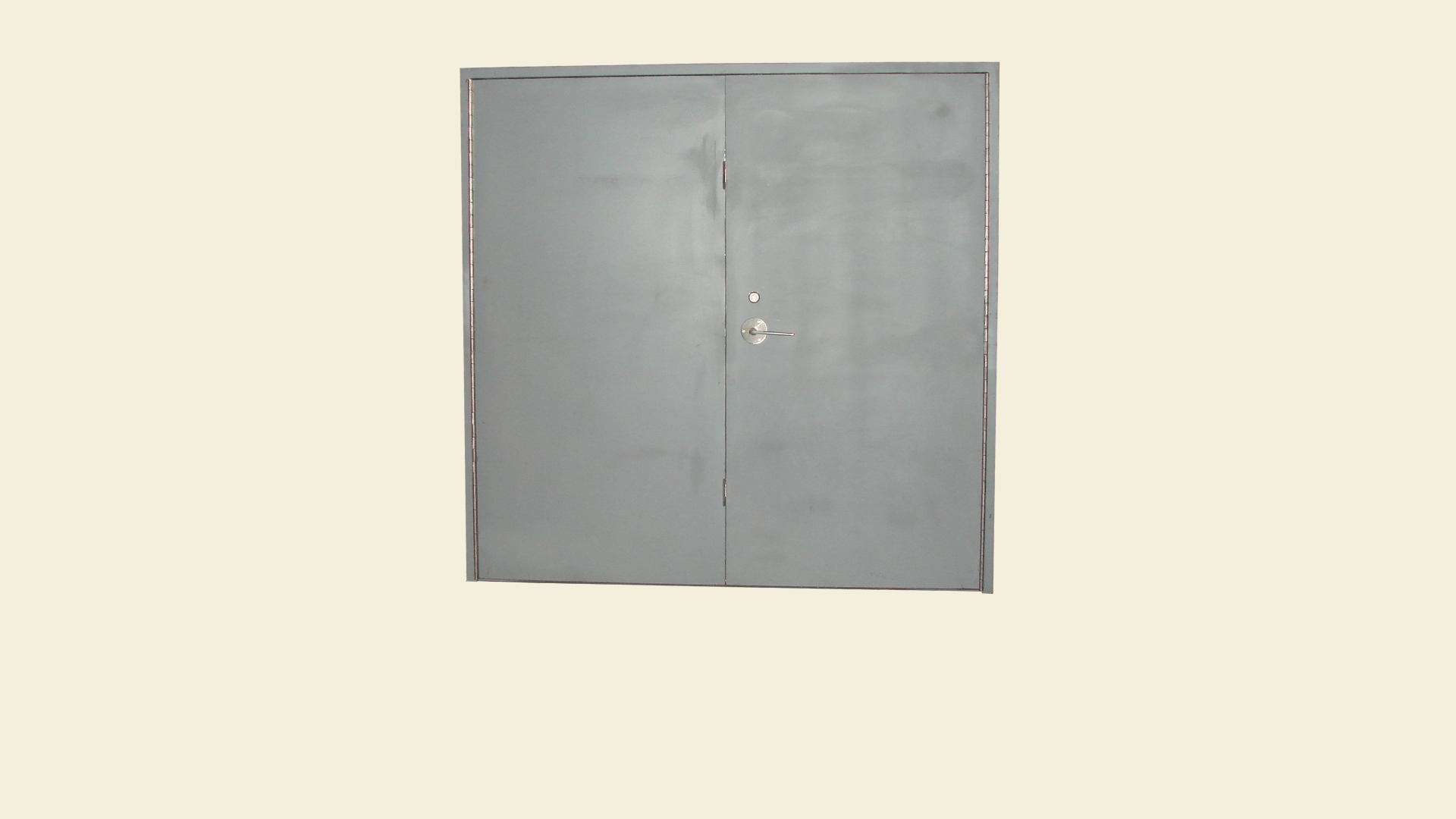

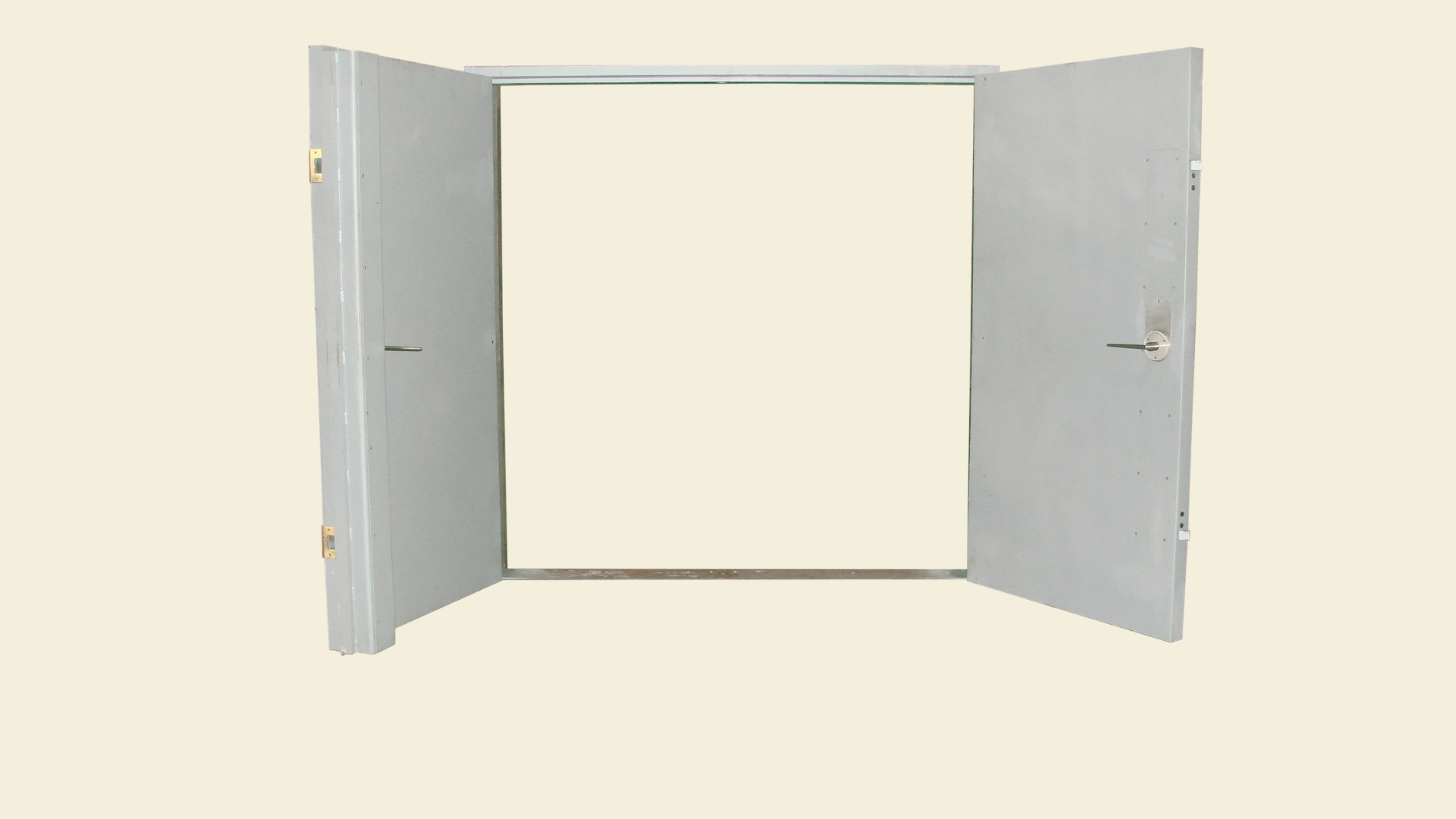

Model DB-X Pair of Mid-range Blast Resistant Doors

Button

Slide title

Model DB-X Pair of Mid-range Blast Resistant Doors

Button

▪ Refineries, petrochemical, plastics and ethylene producers

▪ Chemical plants and other industrial complexes

▪ LNG terminals

▪ Nuclear power plants and generating stations; FLEX projects

▪ Data centers

▪ Munitions storage facilities, magazines, ammunition depots and arsenals

▪ Army proving grounds, explosives test facilities

▪ Missile tests and launch sites

▪ Paint or hazardous material storage rooms; automotive assembly plants

▪ Pharmaceutical or college laboratories and other R&D areas

▪ Bioscience and nanotechnology research buildings

▪ Food processors; paper mills

▪ WTP Water treatment plants

▪ Engine test cells

▪ Extreme weather-related conditions

▪ And numerous other applications

Door Overview

The blast door manufacturer supplies ALL essential components to certify the door system. A swing door – single, pair or multi-folding, includes the frame, anchorage, hinges, door panel(s) and PDI’s own proprietary Sonicbar blast resistant latchset. Sliding doors are furnished with track and trolleys, door panel and blast restraints. Any assembly, swing or sliding, can be power operated via electric, electro-pneumatic, all pneumatic or even hydraulic operation. Prepping for card reader or other access control device is available.

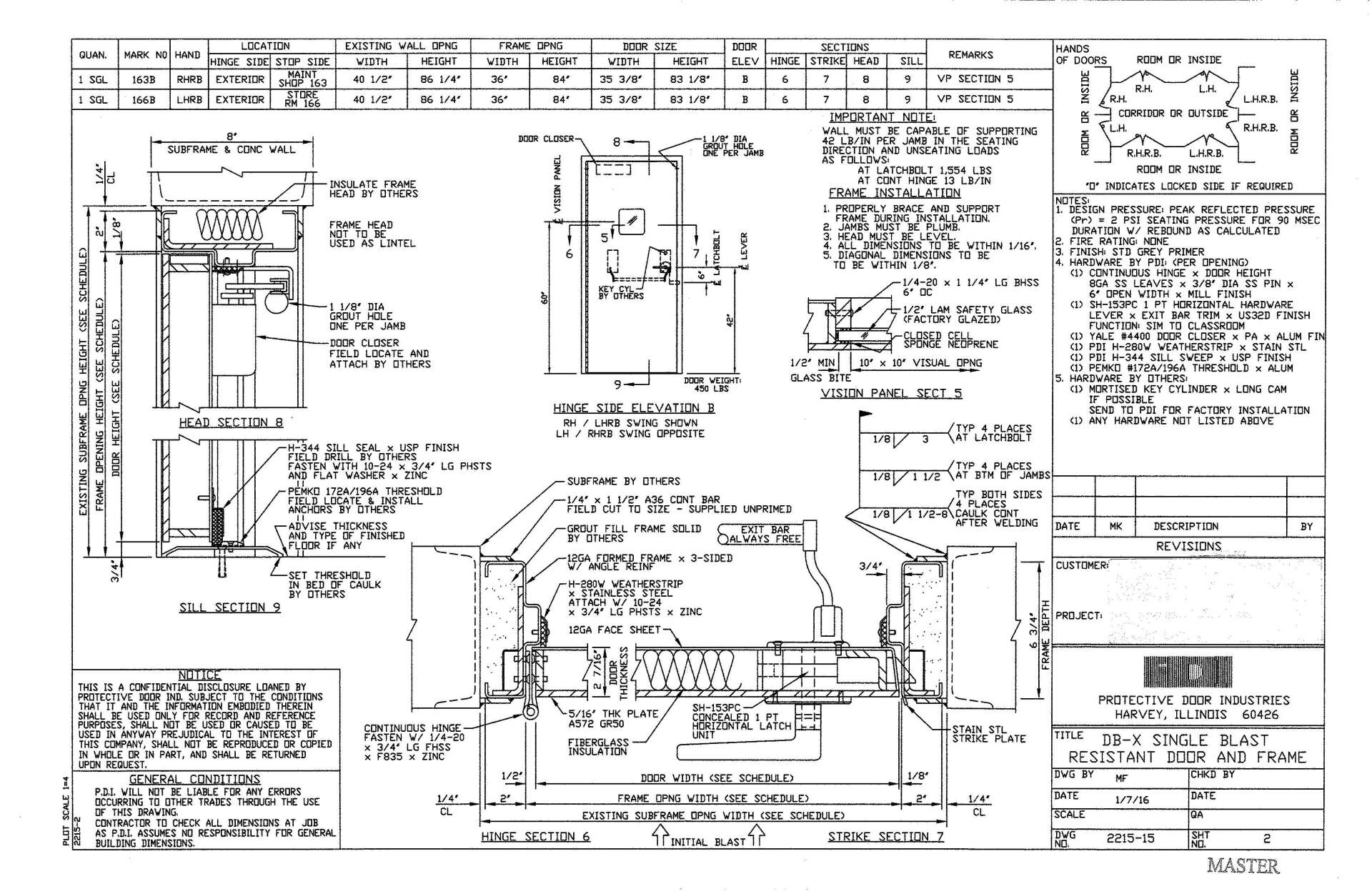

General Reference / Installation Drawing of Model DB-X Single Swing Blast Resistant Door

Door models vary from 1 ¾” thk. for very low range with 1-point or 2-point latching to steel plate construction for mid to high range blast loads with 2-point or multi-point latching. The door leaves are designed for practical solutions, to be as light as possible while allowing maximum protection. PDI’s frames are factory prepared for masonry, concrete, expansion bolt or weld-in anchorage and shipped set-up and welded or KD knock-down where shipping limitations mandate size for large units.

Various components include:

▪ PDI’s proprietary brand of Sonicbar blast resistant hardware

▪ Door closer (required for U.L. Fire Labeled swing doors)

▪ Prep for card reader or other access control device

▪ Prep for power operation with automatic latch retraction

▪ PDI’s own heavy-duty H-280W-SS stainless steel Weatherstripping

▪ Track and trolleys on horizontal sliding doors

▪ Manual or power operation on sliding door systems

▪ U.L. Fire Label

▪ Vision panel

▪ Transom panel

▪ SS Stainless steel door construction

▪ PE stamp on analysis calculations

▪ PDI’s proprietary brand of Sonicbar blast resistant hardware

▪ Door closer (required for U.L. Fire Labeled swing doors)

▪ Prep for card reader or other access control device

▪ Prep for power operation with automatic latch retraction

▪ PDI’s own heavy-duty H-280W-SS stainless steel Weatherstripping

▪ Track and trolleys on horizontal sliding doors

▪ Manual or power operation on sliding door systems

▪ U.L. Fire Label

▪ Vision panel

▪ Transom panel

▪ SS Stainless steel door construction

▪ PE stamp on analysis calculations

Dynamic Blast Door Test

Although the preferred method to evaluate door construction is by analysis calculations (see Report below), PDI tested Model DB-X, a single swing blast door using dynamic plate analysis at BakerRisk in San Antonio, TX using their shock tube test apparatus. The door assembly achieved a response limit of ‘I undamaged’ with no permanent deformation and remained fully operable. Refer to DB-X Dynamic Blast Door Test page for report and video.

Window Overview

Window units are available to provide penetration resistance to weapons or explosives. The frames are fabricated of formed or structural steel and furnished with the appropriate thickness of clear laminated, tempered or polycarbonate glazing as dictated by PDI’s design analysis in conjunction with Wingard computer program.

Specifications and Analysis Calculations

To analyze construction, PDI produces a set of calculations which cover all the required variables and resultant loads. These analysis calculations are performed either statically or dynamically. Many of PDI’s pre-engineered door systems are analyzed with static analysis completed using simple beam diagrams. For those applications involving dynamic analysis, PDI completes a dynamic structural analysis based upon elastic plate design methodology per SDOF Single Degree of Freedom under UFC 3-340-02 ‘Structures to Resist the Effects of Accidental Explosions’ manual (previously Army Technical Manual TM5-1300).

PDI primarily engineers the blast door assembly to meet response categories Medium LOP Level of Protection II or High LOP I for LIFE SAFETY reasons and protection of equipment. Under Level II, the door will experience slight permanent deformation with minor damage; Level I undamaged with no permanent deformation. In both cases, the unit remains latched (elastic) and operable to allow safe ingress or egress after event. The response limits are defined in several standards: Process Industry Practices (PIP) standard PIP STC01018 ‘Blast Resistant Building Design Criteria’, UFC 4-010-01 ’DoD Minimum Antiterrorism Standards for Buildings’ or ASTM F2247 ‘Standard Test Method for Metal Doors Used in Blast Resistant Applications’.

Refer to one of the following specifications applicable to the blast criteria and door configuration or window unit.

Note: If specification is preferred in Word, contact PDI.

Slide title

Model DB-100-SL Pneumatically Operated Horizontal Sliding Low Range Blast Resistant Door Assembly

Button

Multiple Capabilities

The specification on most door and window units cover blast resistance only, but PDI also receives requests to build doors for multiple threat levels. Assemblies may have an added security threat such as bullet resistance to withstand U.L. 752 Standard for Safety Level 8 /or/ NIJ Level IV. In this case, PDI incorporates certified armor plate into the design with armor plate welded to blast / threat side. The heavy duty 10ga. construction on the DB-100 door allows PDI to certify it for U.L. 752 Level 3 SPSA and also bear a Fire Label. Other combinations include blast and missile resistance, pressure and sound control, or even a blast / bullet / missile / tornado resistant door system.

WHATEVER WORKS!!!

Replacement Doors

Consider replacement if site has some fairly ancient doors that are difficult to operate or adjust, or in deteriorating rusty condition. PDI may be able to re-use the frame, especially if it is cast-in thereby saving the expense of a complete tear-out. If the frame has been welded onto an embedded sub-frame, PDI should be able to replace entire door system with preferably a lighter assembly. There are options available, contact PDI technical staff.

Product Selection

The following chart lists PDI’s Sonicbar pre-engineered and custom steel door and window models. The model number is dependent upon the pressure criteria – static or dynamic load along with door size and configuration. An evaluation of each system is performed in-house with blast analysis calculations submitted for engineering review. Sample CAD drawings and specifications are offered by clicking on the Selector Chart.

Consideration must be given to factors that impact the design such as static or dynamic Pr peak reflected load, seating or unseating direction, rebound percentage, time duration, pressure-time history, impulses, exposure area, door size, fire rating, etc.

PDI Door Models

Design based on static blast analysis

| DB-100 | Low Range Blast Resistant Swing Door |

|---|---|

| DB-100-SS | Low Range Stainless Steel Blast Resistant Swing Door |

| DB-100-SL | Low Range Blast Resistant Sliding Door Unit |

| DB-200 | Low to Mid-Range Blast Resistant Swing Door |

| DB-200LT | Low to Mid-Range Blast Resistant Swing Door |

| DB-200-SL | Low to Mid-Range Blast Resistant Sliding Door |

| DB-200-VL | Low to Mid-Range Blast Resistant Vertical Sliding Door |

| DB-200M | Mid-Range Blast Resistant Swing Door |

| DB-10 | Mid to High Range Blast Resistant Swing Door |

| DB-20 | High Range Blast Resistant Swing Door |

| DB-50 | Very High Range Blast Resistant Swing Door |

Note: U.L. Fire Label is available on DB-100, DB-200 and DB-10 swing door models.

Design based on dynamic blast analysis:

| DB-X | Low to Very High Range Blast Resistant Swing Door |

|---|

Design based on blast analysis and ballistic and/or missile criteria:

| DB-100B | Low Range Blast (Static) and Certified to U.L. Level 3 SPSA Bullet Resistant Swing Door |

|---|---|

| DB-10B | Mid to High Range Blast (Static) and Bullet Resistant Swing Door |

| DB-XB | Low to High Range Blast (Dynamic) and Bullet Resistant Swing Door |

| DB-XM | Low to High Range Blast (Dynamic) and Missile Resistant Swing Door |

Slide title

Model DB-X Mid-range Blast Resistant Single Swing Exterior Doors

Button

Design based on FEMA 361 pressure and tornado criteria:

| DT-200 FEMA 361 | Tornado Resistant Swing Door |

|---|

Design based on pressure or airtight analysis:

| DB-150 | Nominally Airtight Swing Door |

|---|---|

| DA-100 | Airtight / Gastight Swing Door |

Design based on static or dynamic analysis:

| WB-X | Blast Resistant Window Unit |

|---|

Plus, many more designs depending upon criteria.

PDI fabricates doors and windows at custom sizes and ratings beyond the basic products listed. Contact sales@protectivedoor.com or 708/225-3539.

Consult the Establishing Blast Criteria sheet or ‘Basic Insights Specifying Special Purpose Doors and Windows’ along with product specifications for support qualifying the project’s blast criteria.

Note: These are simply aids, the door manufacturer does not determine blast criteria. Analyzing the design load is the responsibility and liability of the Engineer of Record.

Pertinent information:

- Blast/Pressure/Missile/Tornado Resistant Selector Chart page

- ‘Basic Insights Specifying Special Purpose Doors and Windows’

- ‘Analysis Calculations versus Laboratory Test for Blast Resistant Doors’

- Specifications:

▪ Specification for Static Analysis – Swing Doors

▪ Specification for Dynamic Analysis – Swing Doors

▪ Specification for Static or Dynamic Analysis – Sliding Doors

Protective Door Industries

15700 Lathrop Ave.

Harvey IL 60426-5118 USA

A leading manufacturer of steel doors, windows and barriers for blast, pressure, missile, tornado and bullet resistance, sound control, security and more since the 1960's.

Protective Door Industries. Designed by SmallBee