Protective Door Industries

15700 Lathrop Ave.

Harvey, IL 60426-5118 USA

Overview of Sound Control Assemblies

Protective Door Industries (PDI) Sonicbar sound retarding steel doors and windows are engineered to provide the maximum sound performance rating specified to eliminate noise from potential sources such as an engine test cell or external street noise overheard on a theatrical or movie stage, as well as many other applications.

Doors are available in a broad range of sizes, high STC ratings and operational configurations – single swing, large pairs and multi-folding, horizontal sliding and vertical lift. To assure efficient sound control, they have high mass, effective internal damping and compression or inflatable air seals.

Sonicbar sound doors and windows have been tested by Riverbank Acoustical Laboratories according to ASTM E-90 standards.

Slide title

Model DS6-61L Engine Test Cell Door

Rated for 59 STC

Button

Slide title

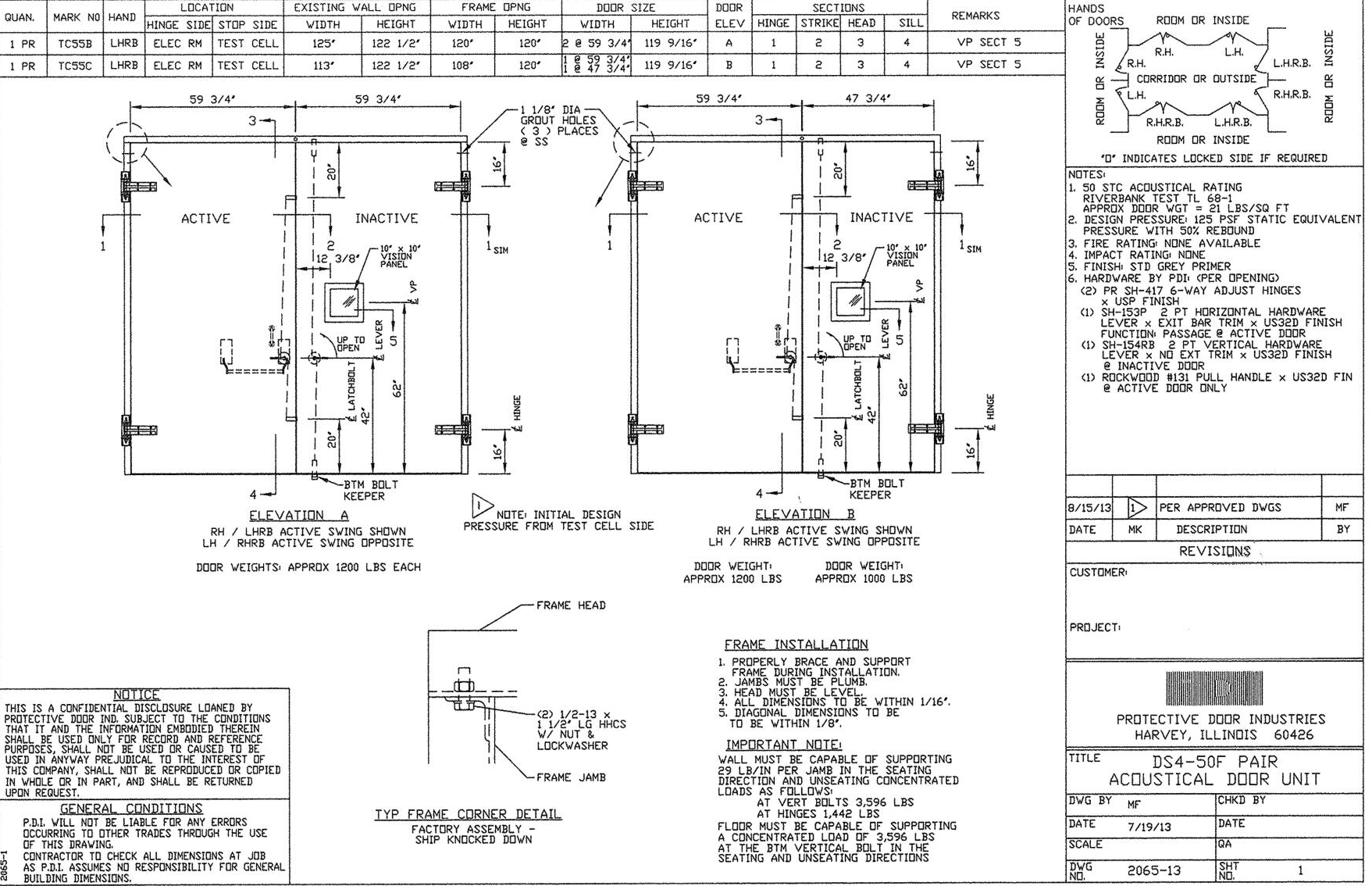

Model DS4-50F Large Pair of Acoustical Doors

(Backstage)

ButtonSlide title

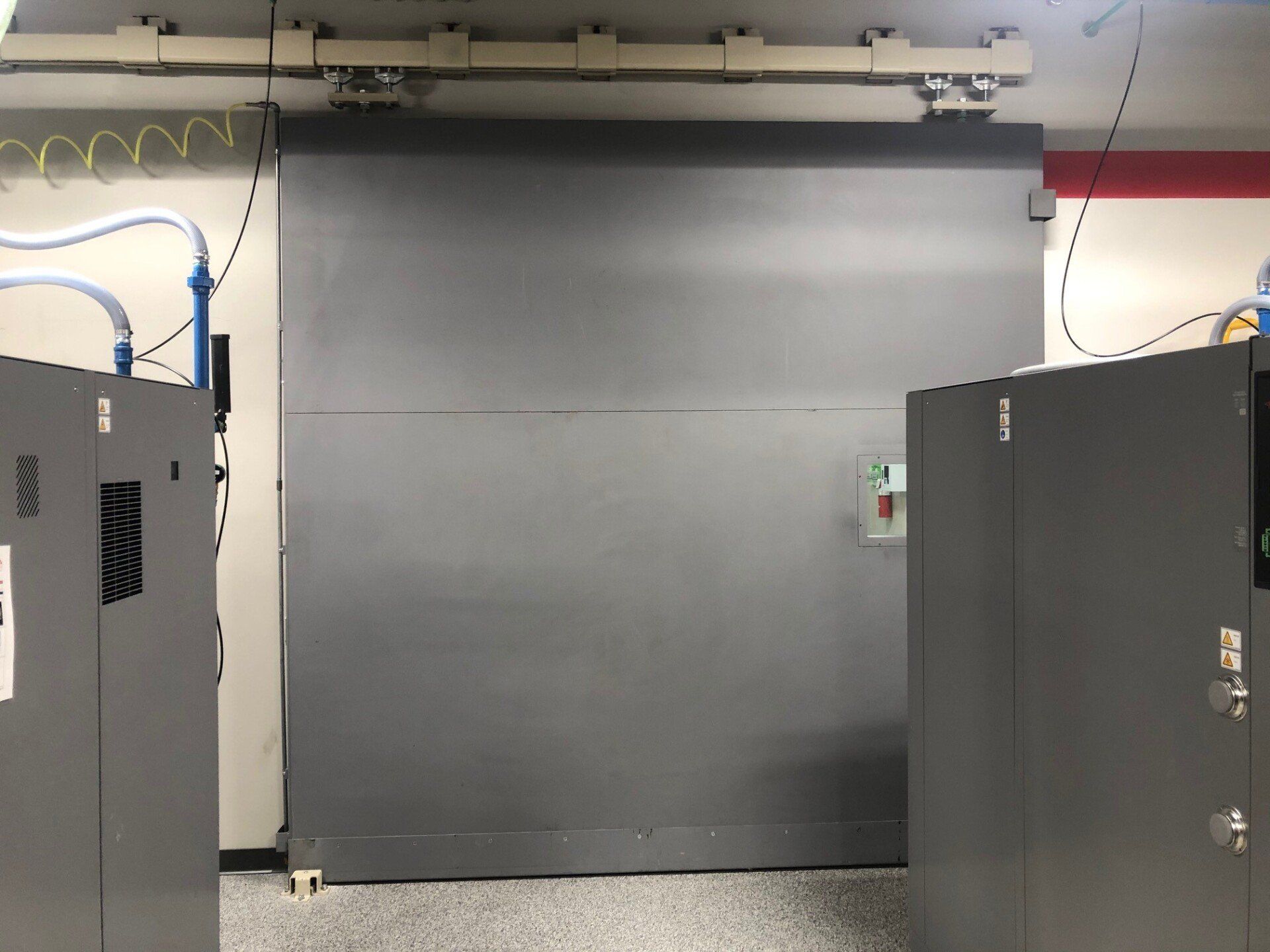

Model DS4-50-SL Horizontal Sliding Sound Control Door

at Performing Arts Center

ButtonSlide title

Model DS6-58R Sliding Exterior Acoustical Theatre Door

(blocks street noise)

Button

Applications include:

▪ Helicopter and aircraft jet engine test cells

▪ Auto and diesel engine test cells

▪ Tractor and combine engine test cells

▪ Missile tests and launch sites

▪ Data centers; computer rooms

▪ Nuclear power plants

▪ Military applications, AFB Air Force Bases, NAS Naval Air Stations

▪ Performing and Fine Arts Centers

▪ Sound stages

▪ TV and radio stations

▪ Recording studios

▪ Heavy construction equipment manufacturers

▪ Laboratories and R&D areas

▪ And any location involving complex noise spectra or high STC rating.

STC Rating

Acoustical consultants use a qualifying method to quantify and compare the sound attenuation. The STC Sound Transmission Class rating is the standard descriptor used to measure the assembly’s sound proofing ability. PDI excels perfecting products with higher STC ratings, primarily +45 STC for large oversized hinged and sliding doors, and ratings up to +61 STC for personnel size swing door applications.

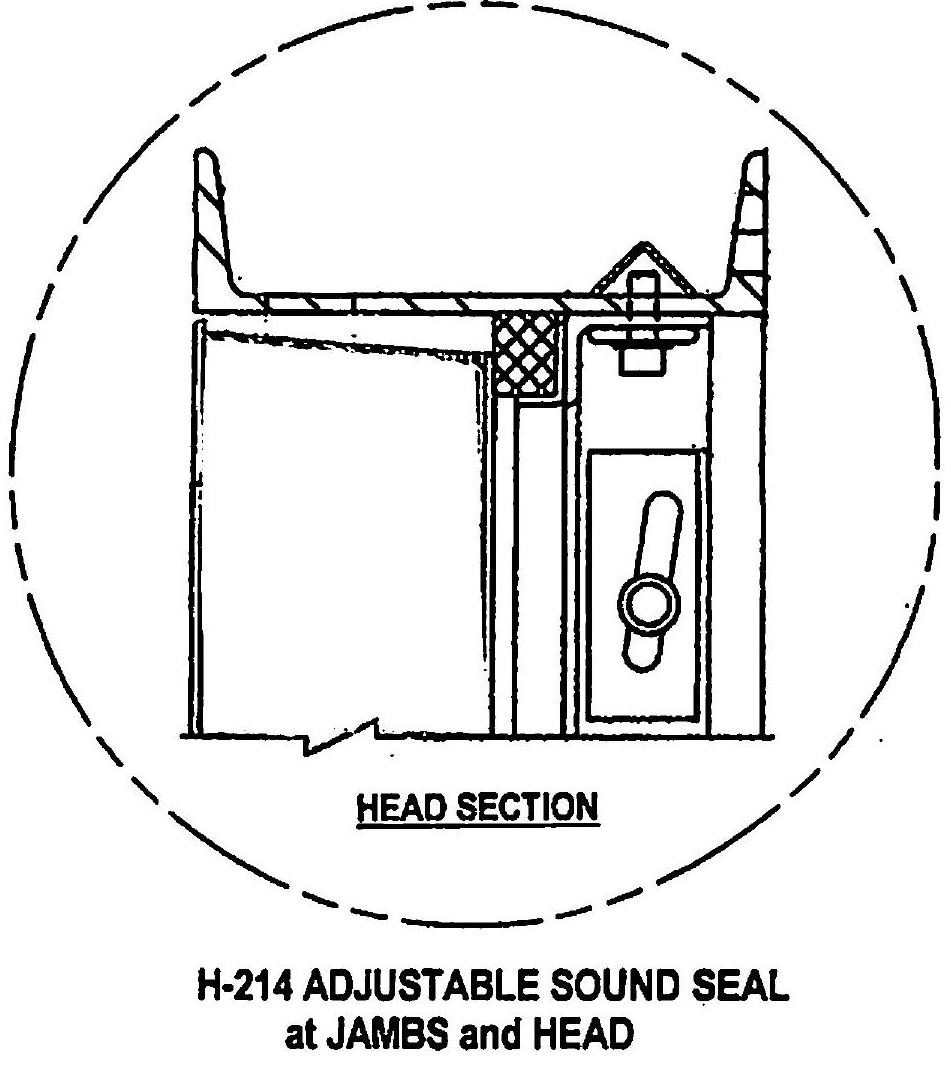

The Importance of Sonicbar Adjustable Sound Seals

A major area of the door construction to achieve good sound attenuation is the sealing of the door’s perimeter. The gasketing on a swing door should always be specified as adjustable to assure continuing on-the-job performance. PDI’s compression type closed cell neoprene seals are preferred for reliability and long life. Although flush sills closed by an automatic door bottom are more popular, a low sill provides a better noise barrier and the raised sill is the best performer if its’ relative inconvenience can be tolerated. Refer to sound control door drawings on the selector chart for types of gasketing manufactured by PDI.

Swing Doors

PDI’s acoustical swing doors commonly found at engine test cells retard the peak noise frequency of an engine ramped up to full throttle. Large pairs installed at performing arts centers are aimed at keeping exterior noise out. These swing door and frame assemblies are of all steel non-combustible construction. Door panels have acoustical fill with interior formed stiffening reinforcements shop welded full height so that faces will not be connected except at edges. Frame anchorage is critical, especially oversized hinged doors or those with high STC ratings and should be incorporated into the early planning stages of the building’s construction. Exclusive PDI’s heavy duty concealed Sonicbar hardware with 2-pt. latching along with PDI’s SH series 6-way adjustable steel hinges and perimeter sound seals assure ease-of-operation, secure latching and efficient sound sealing.

General Reference Drawing of DS4-50F Pair of Engine Test Cell Doors

at Tractor / Combine Manufacturing Plant

Sliding Doors

To save floor space usually required by conventional swing or hinged doors, PDI engineers horizontal sliding or vertical lift doors to meet requirements, regardless of size. Sliding doors are furnished with track and trolleys, door panel and restraints. Operating system can be manual with pneumatic controls or completely power operated with an electro-pneumatic system to move door. These large openings utilize PDI’s exclusive H-265 4-sided Auto-air Seal system that is air actuated to inflate seals when closed and instant spring return to open and deflate seals before door starts traveling. With the variances in wall and floor construction, even meeting minimal tolerances, the inflatable seals effectively cover and seal gaps between door and adjacent construction to stop any possibility of sound transmission.

Various components include:

▪ PDI’s proprietary brand of Sonicbar heavy-duty hardware

▪ PDI’s own perimeter adjustable Sound Seals or Auto-air seal system

▪ Prep for card reader or other access control device

▪ Track and trolleys on horizontal sliding doors

▪ Combination pressure/blast resistant and sound control construction

▪ Flush or low sill conditions

▪ Optional vision panel

▪ Door closer

▪ Manual or power operation

Sound Control Window Overview

PDI’s sound retarding fixed steel window units provide visual contact with safety for operating personnel. Units are normally dual glazed with each piece of glass capable of being removed independently. A perforated liner between stops allows for additional air space to contribute to the noise barrier condition. The steel frame can be engineered with a sloped pane for reflection control. Test cell windows commonly incorporate bullet resistant glass on test side as a precaution against projectiles from spalling engine parts. Glazing compound and PDI’s proprietary acoustical gasketing are always included in the window package.

Models and Specifications

The following chart lists PDI’s Sonicbar Acoustical Door and Window Systems. The model number is dependent upon the sound criteria and sill condition along with door size and configuration. An analysis of each system is performed in-house with sound certification submitted for engineering review.

Slide title

Model DS4-50-FS Sliding Acoustical Door

Lab at Automotive Components Manufacturer

Button

Slide title

Model DS4-50-FS Sliding Acoustical Door

Lab at Automotive Components Manufacturer

Button

Sound Control Door Assemblies and Window Units

| DS4 | up to 52 STC | ACOUSTICAL HINGED DOOR WITH LOW or FLUSH SILL |

|---|---|---|

| DS6 | 53 to 61 STC | ACOUSTICAL HINGED DOOR WITH LOW or FLUSH SILL |

| DS4-50-FS | 50 STC | ACOUSTICAL HORIZONTAL SLIDING DOOR |

| WS | up to 56 STC | ACOUSTICAL WINDOW UNIT |

Plus, more designs depending upon criteria.

Refer to the following specifications applicable to the sound criteria and door configuration.

Note: If specification is preferred in Word format, contact

PDI.

Product Selection

Refer to the Sound Control Selector Chart for sample CAD drawings and specifications of assemblies designed for a specific STC rating. Click on a drawing for preview of the door or window unit’s construction and components or consult with PDI’s Technical staff at sales@protectivedoor.com or 708/225-3539.

Protective Door Industries

15700 Lathrop Ave.

Harvey IL 60426-5118 USA

A leading manufacturer of steel doors, windows and barriers for blast, pressure, missile, tornado and bullet resistance, sound control, security and more since the 1960's.

Protective Door Industries. Designed by SmallBee